Loyal-Tec take care your equipment, but also the demands of your operating condition in process. Combined with CFD and analysis of component inspection, our experience enables to make your equipment better and better.

Through the process of inferring the module of original pump designers, Loyal-Tec provides the solution for below issues by our redesign capability.

- Insufficient performance on capacity or differential pressure

- High running cost due to poor efficiency or overdesigned condition

- Vibration due to the duty point close to minimum flow

- Cavitation due to insufficient NPSH

- Insufficient budget, space, or time to change pumps of above condition

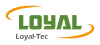

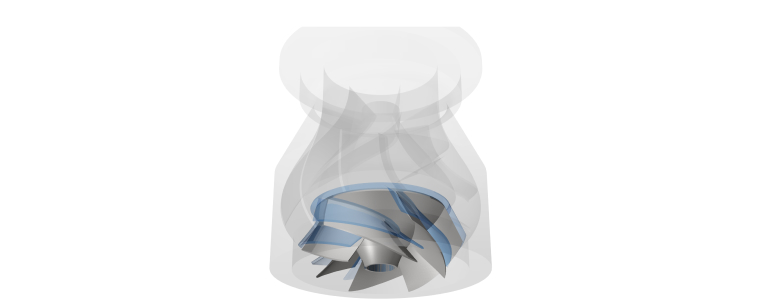

Computational Fluid Dynamics

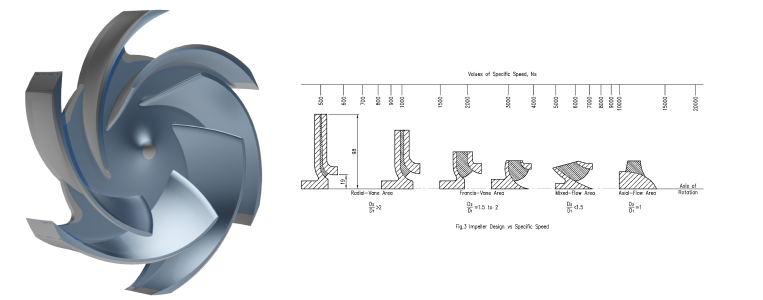

CFD simulation makes it possible to visualize the flow conditions inside a centrifugal pump and provides valuable information about the pump’s hydraulic design. The CFD simulation results are used to calculate and predict the performance of a centrifugal pump. We can re-designed pump, the performance can be calculated and analyzed close to real condition.

Loyal-Tec has fully sufficient capability of CFD flow simulation support to our customer

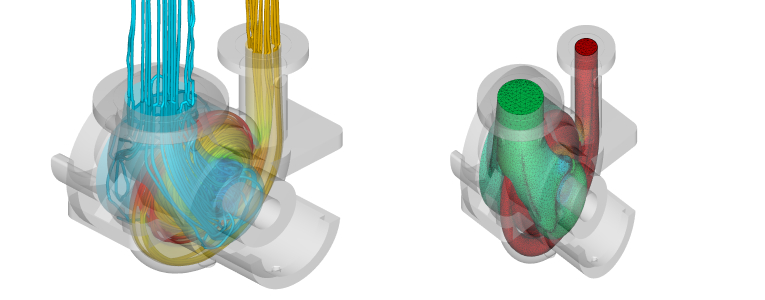

Increase Differential Head

Through the redesign of impeller, The total differential head could be increased by up to 20% based on the original impeller installation dimension.

Increase Capacity

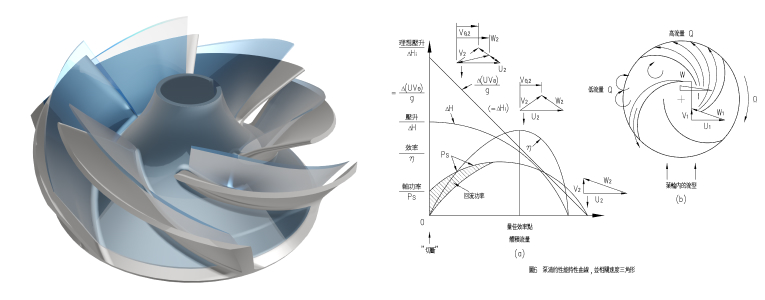

By redesign the outer width of an impeller and enlarging casing volutes, The pump capacity could be increased by up to 50% based on the original impeller installation dimension.

Improve Efficiency

Through redesign the flow-way section area of an impeller and casing volutes, The internal counter-flow inside the impeller flow way will be reduced, Pump efficiency could be improved and best efficiency point (BEP) could be removed close to real duty point.

Reduce NPSH-required

By design the diameter of impeller suction or the front side of blades, The liquid flow rate will be reduced at suction area.

This will increase liquid static pressure under the same duty point and the pump NPSH-required will also be reduced.

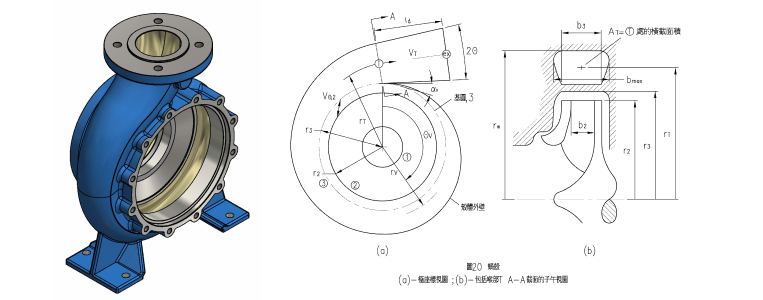

Centrifugal Pump Casing Reverse Engineering

Through redesign engineering of casing volute section, diffuse angles, and water-cut, the volute casing, bowl, diffuser can be re-established back to original module matching original performance.